“Turnkey” RETROFITS and INSTALLATIONS from DKHV – an overview

DKHV specialises in offering “turnkey” solutions for extensive and complex retrofits and installations at a fixed price.

“Turnkey” means from one source: DKHV project management including commissioning and coordination of the mechanical and electrical installation work by our partners.

Projects carried out on a Battenfeld, Kuhne and W&H line, 3-layer in each case:

- PLAST-CONTROL

- Austausch alter Maschinensteuerungen (EXTROL, Siemens) gegen PLAST-CONTROL NAVIGATOR

- Upgrade conveying system and gravimetric dosing units

- Upgrade IBC control and width measurement and control

- Temperature zone control incl. electricity measurement and load shedding

- Austausch alter Maschinensteuerungen (EXTROL, Siemens) gegen PLAST-CONTROL NAVIGATOR

- WEMA

- Replacement of ALU heating belts with heating belts from WEMA

- New blowers incl. brackets

- New covers for extruders

- Replacement of ALU heating belts with heating belts from WEMA

- Lebbing

- New frequency converters (incl. mounting plates) and AC-motors

- Retrofit winder: New drive technology (frequency inverters + motors) and new control software

- Current safety standard on the complete system incl. winder

- DKHV

- Mechanical installation

- Electrical wiring incl. removal of old cables

- Project management

- Our team at the construction site

The following tools help us with the processing:

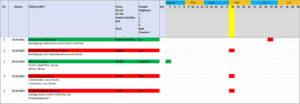

PROJECT STATUS Report

In the PROJECT STATUS all points are recorded and it is sent regularly to all project members.

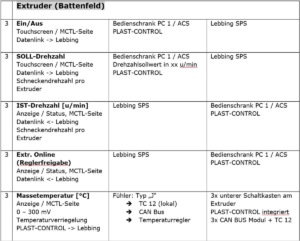

LIST OF FUNCTIONS AND SIGNALS

With this list, the responsibility of the work is determined and you can quickly see what is still to be done.

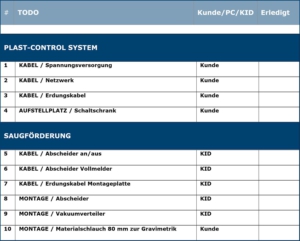

TODO-List

This list is used to determine who is responsible for the work and to quickly identify which work still needs to be carried out.