PLAST-CONTROL: Central vacuum systems & pipelines

A central vacuum supply for the complete production offers many advantages compared to the setup with individual, decentralised vacuum pumps and pre-filters per system:

- Significantly reduced energy consumption

- High reliability

- Reduced maintenance effort

- Only one pre-filter necessary

- No waste heat in the factory hall

- Can be installed in the production hall due to effective noise protection

- Simple expansion

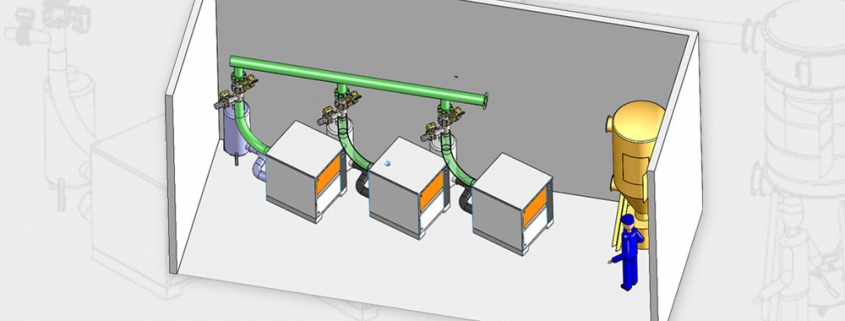

2 examples of existing installations:

Vacuum supply for max. 10 blown film extrusion lines

Max. capacity: approx. 3,500 kg/h

Vacuum pumps: 3x 22 kW

Central filter: 1x PCP 30000

Length of vacuum line: approx. 100 m

Vacuum supply for max. 8 blown film extrusion lines

Max. capacity: approx. 2,700 kg/h

Vacuum pumps: 2x 22 kW

Central filter: 1x PCP 11300

Length of material line: approx. 70 m

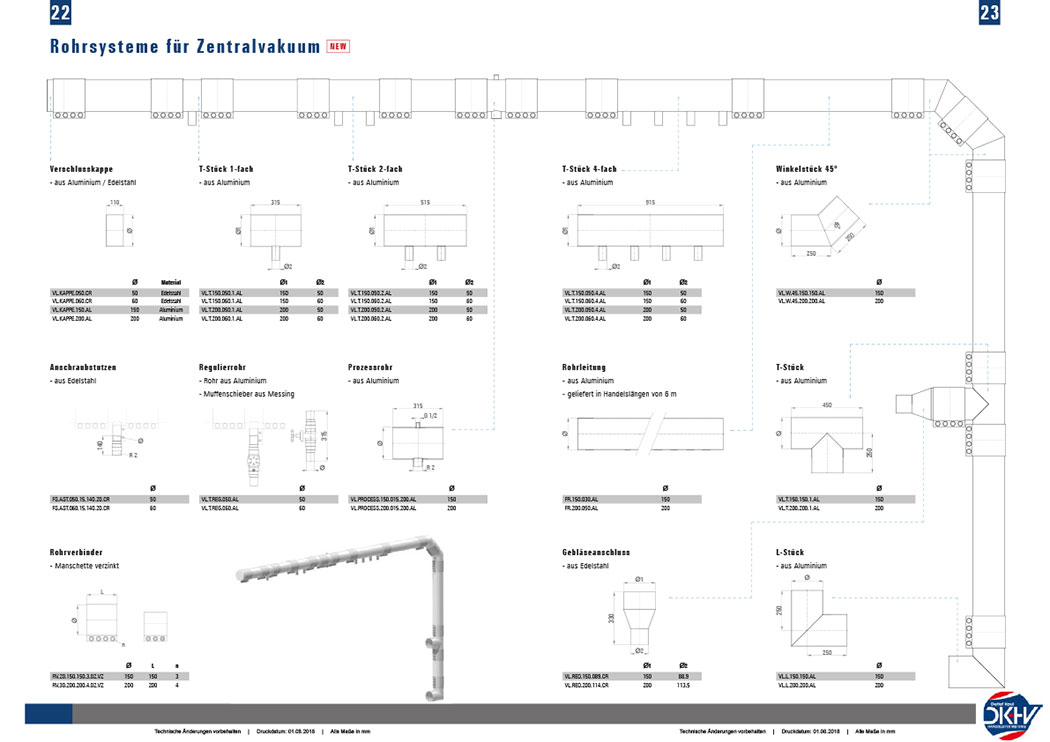

The installation of the central vacuum system and the piping can be done while the extrusion lines are still in production. DKHV offers central vacuum systems incl. piping, outlets, coupling stations (among others) and their installation.

A central vacuum system can be retrofitted with the new pipe system in a production hall without much effort.

We will be happy to advise you!